Power up: Engineering students gain valuable hands-on experience in Electric Vehicle Safety Lab

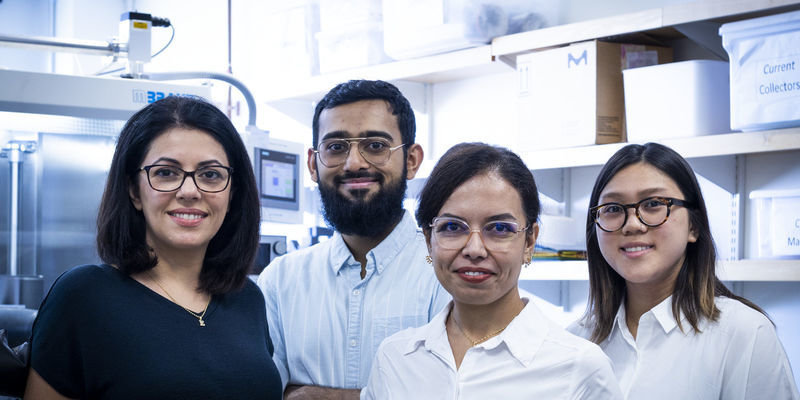

Graduate and undergraduate students in the lab, directed by Associate Professor Elham Sahraei, test and model batteries in electric vehicles.

Before working in Temple’s Electric Vehicle Safety Lab, Monica Yoo didn’t realize how dangerous or defective batteries could be. “My family owns a Tesla, and now I think about how the batteries operate inside of it.”

As an undergraduate researcher in the lab, she tests and models lithium-ion battery cells using industry-level equipment and software. “It’s a great opportunity because a lot of us are looking for internships and experience before we graduate, so working in this lab is really helpful,” said Yoo, who’s from Orange County, California.

“I’m a hands-on person, so using the different tools in the lab is fun,” added Yvette Lai, a mechanical engineering major from Austin, Texas, who’s in the +1 bachelor to master’s accelerated degree program. “The lab is very collaborative. It feels like you’re working toward something together. I’ve learned how to use new programs and present to people in the industry. I look forward to doing more of that.”

Working in the Electric Vehicle Safety Lab gives students the opportunity to contribute to an emerging field.

“The type of research we do is very unique,” said Elham Sahraei, director of the Electric Vehicle Safety Lab and associate professor of mechanical engineering. “Many researchers focus on other aspects of batteries like how to make more energetic materials and batteries that maintain their charge longer. This lab is mainly focused on crash safety.

Temple is gaining a greater reputation for research that’s in demand for the future of green transportation. Electric vehicle safety is not well-known or well-optimized, so we need to train people to help make electric transportation safer and more efficient.”

The main goal of the lab is to help car companies understand the causes of battery failures in car crashes and how to prevent them. Researchers test the batteries’ limits to predict what will happen. Those predictions allow for a safer product and reduced costs.

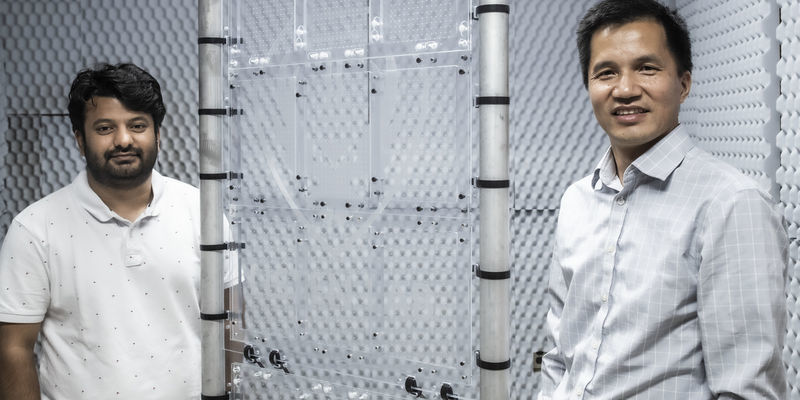

Located in the College of Engineering, the lab includes facilities for crash safety testing, battery recycling, cell-making lines and computational work. Both graduate and undergraduate students participate.

Graduate students advance battery safety in various areas. This work includes combining models of mechanical safety with electrochemical models and testing and developing failure criteria for batteries. Students also take battery models at the cell level to make battery pack models that can be integrated into vehicles. Additionally, they mentor undergraduate students in the lab, training them to model and test.

“In our lab, we get to do a variety of things and gain so much knowledge,” said PhD mechanical engineering student Huzefa Patanwala, who grew up in Dubai. “Having experience in both modeling and testing prepares you for working in the industry.”

“It’s exciting when I complete a project or solve a difficult problem in the lab. It increases my motivation and passion,” added Yihan Song, who’s also a PhD student in mechanical engineering and hails from Beijing.

Both Patanwala and Song recently completed internships at Tesla, where they were able to apply what they’ve learned in Temple’s Electric Vehicle Safety Lab. “I learned what we do in the lab is relevant to the industry,” said Patanwala, who did component testing in the cell engineering department at Tesla. “The lab afforded us this opportunity. Researching battery safety in electric vehicles is very relevant, interesting and novel. It’s cool to be part of something new.”

“Usually, my graduate students don’t need to search for jobs because companies often reach out to them first,” said Sahraei. “This work prepares both undergraduate and graduate students for their future careers. They’ve been in demand for jobs at companies like Apple and Tesla.”

Recently, Sahraei launched the Center for Battery Safety, which will lead research around the safety of batteries when they crash and mechanical deformations causing internal short circuits. Major companies and institutions such as Ford, GM, Stellantis, Tesla and the National Highway Safety Transportation Administration attended the kickoff meeting of the Center for Battery Safety.

This new center has ultimately come to fruition thanks to the work of Sahraei and her graduate and undergraduate researchers in the Electric Vehicle Safety Lab.

“I’ve learned a lot about batteries in electric vehicles, and having experience with the modeling software and testing machines will help me in my future career,” said Yoo.