Researchers seek efficient, cost-effective renewable energy solutions

Since the first Earth Day was held on April 22, 1970, the United States has slowly tried to wean itself off of traditional, fossil fuel-based methods of providing energy toward greener, renewable energies.

From geothermal to solar to wind power, Temple researchers are engaged in a variety of projects to develop new renewable energy technologies, to make them more efficient and more cost-effective.

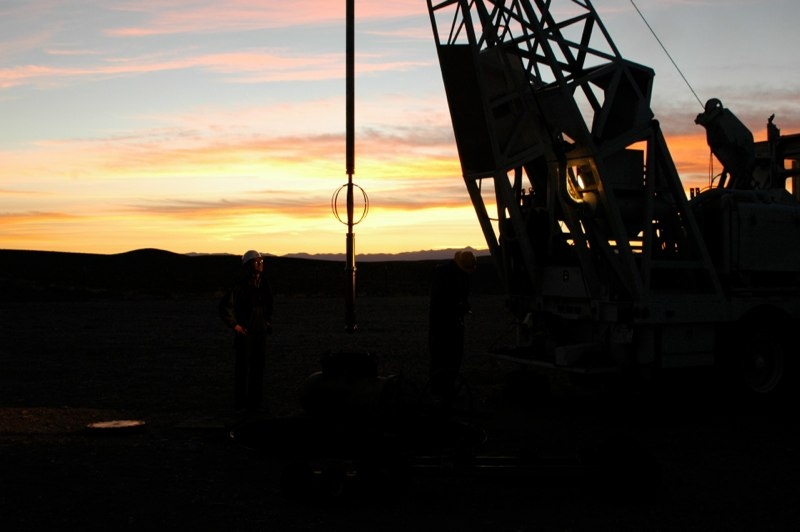

Nicholas C. Davatzes, assistant professor of earth and environmental science in the College of Science and Technology, is involved in about a dozen projects exploring the use of natural and abundant heat below the Earth’s surface to generate electricity.

According to the U.S. Geological Survey, geothermal energy systems have potential to generate nearly 600,000 megawatts of electric of power generation, but the technology to tap these resources is still largely underdeveloped. Each megawatt of geothermal-generated electric can power approximately 1,000 U.S. households.

“Most of the technology for making electricity involves converting heat into work and then work into electricity,” said Davatzes. “Usually we burn things like fossil fuels to make the heat, but with geothermal, Mother Earth provides the heat.”

Davatzes, who has received more than $3.5 million in geothermal research funding since joining Temple in 2008, said geothermal doesn’t get as much attention as it should, but one of its key advantages is that it provides a constant output. “It doesn’t show the daily variation in power output that most of the other renewables show,” he said.

As with all energy technologies, the cost of producing the energy relative to its return plays a key role in its development. Davatzes said that drilling success in geothermal is relatively low, but the cost to drill wells is high, so it can take more than a decade to realize a return on investment. That’s why he is working with geothermal industry leaders like ORMAT, AltaRock and Nevada Geothermal Power, as well as the U.S. Department of Energy, U.S. Geological Survey and U.S. Navy, in places like Nevada and Oregon to figure out how to successfully drill geothermal wells.

In addition to where to drill the wells, Davatzes is also studying ways to get water to flow better through the fractures in the hot rock below the surface — a key component in successful geothermal systems — by enhancing existing fractures or creating new pathways to circulate the fluid through these natural systems.

“A couple of these projects are pretty close to demonstrating that the technology is there to turn huge volumes of the rock below the surface of the western United States into clean, sustainable energy,” he said.

Svetlana Neretina, assistant professor of mechanical engineering and director of the renewable energy laboratory in the College of Engineering, is looking at a better way to harness the power of the sun through the development of next generation solar cells which combine thin films and nano-materials.

“If you look at the solar cell market, the dominant material is silicon,” said Neretina, who joined Temple in 2009.

She and her research group are using a pulsed laser deposition system to develop solar cells using cadmium telluride (CdTe) thin films and nanostructures. While the efficiency of current CdTe thin film solar cells is lower than that of silicon technologies due to defects and impurities, it is significantly cheaper to manufacture.

“We are trying to make CdTe single crystal films with far fewer defects,” said Neretina, who began this project through a Temple seed grant in collaboration with chemistry’s Bradford Wayland and is now supported through a NSF CAREER grant. “If we achieve our goals, it should increase efficiency, while reducing the cost to produce solar cells.”

Mechanical Engineering Professor Shih-Jiun Chen’s research is focused on how the design and pitch control of wind turbine blades can make the turbines more efficient and less noisy.

“These days, the wind turbines are bigger, so they rotate slower,” said Chen, an expert in aerodynamics. “Normally, you need winds of about 15-20 miles-per-hour to make a turbine rotate, but with better design and pitch control, you will only need about a 7-10 miles-per-hour wind. By making them more efficient, they will turn easier in less wind, which generates more power.”

Chen, who took a study leave in spring 2010 in Taiwan to research wind turbines, has been looking at blade designs that mimic a bird’s wing and a whale’s fin.

Other Temple projects involving renewable energies include Chen and Civil and Environmental Engineering Professor Michel Boufadel’s collaboration with industry on the development of a geothermal heat pump; Electrical and Computer Engineering Associate Professor Li Bai’s study of the efficiency of solar- and wind-powered LED street lights; and Associate Professor of Mechanical Engineering Parsaoran Hutapea’s study of the performance of polymer electrolyte membrane fuel cells, which use hydrogen to produce electricity to power vehicles.