Hospital immersion inspires bioengineering students’ project

The bioengineers-in-training are creating a device intended to help physicians place chest tubes more accurately, improving patient outcomes.

For senior bioengineering major Dominick Threeton, watching doctors at Temple University Hospital perform procedures that require them to place chest tubes in patients inspired an idea: What if there were a device to make placing the tubes more precise?

Tube thoracostomy—insertion of a tube into the chest cavity to drain fluid or air—is commonly used as a lifesaving intervention for patients who have sustained a traumatic injury, such as a gunshot wound, or have conditions that affect their lungs. But, as Threeton learned during his six weeks shadowing physicians during the BioDesign Clinical Immersion Internship in Summer 2018, placement of the tubes has a complication rate as high as 30 percent.

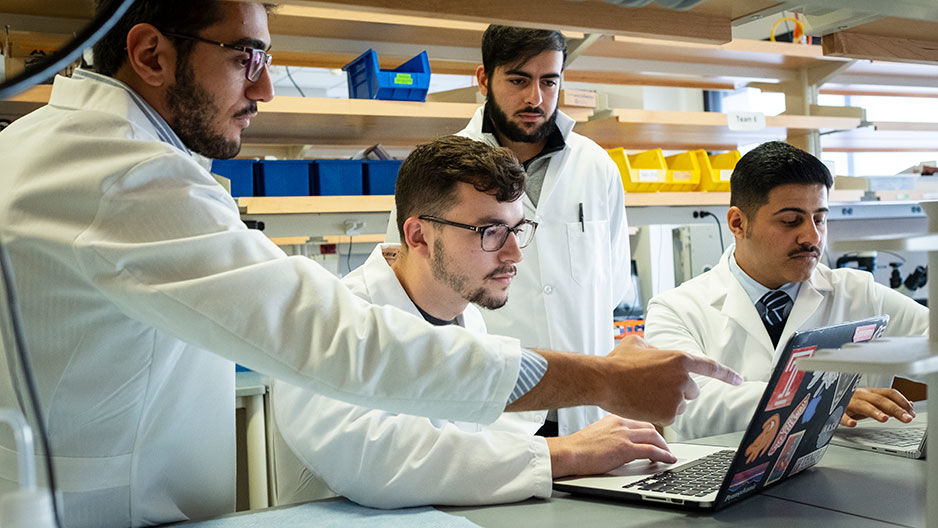

Threeton thought there had to be a bioengineering solution to help doctors more accurately place the tubes. So in Spring 2018, during a seminar course to prepare for the Senior Design capstone, he enlisted the help of friends Waleed Nowayti, Muath Giaddui and Majd Tobaje—also bioengineering majors—to design and create the device. For Senior Design, the yearlong capstone all engineering majors take, small groups of students work together to devise an engineering solution to a problem. Friends through their classes, Threeton, Nowayti, Giaddui and Tobaje—all seniors graduating in 2020—decided to work together on the chest tube device.

“Doctors save lives,” Nowayti said. “As bioengineers, we see that we can help improve the way [they do that].”

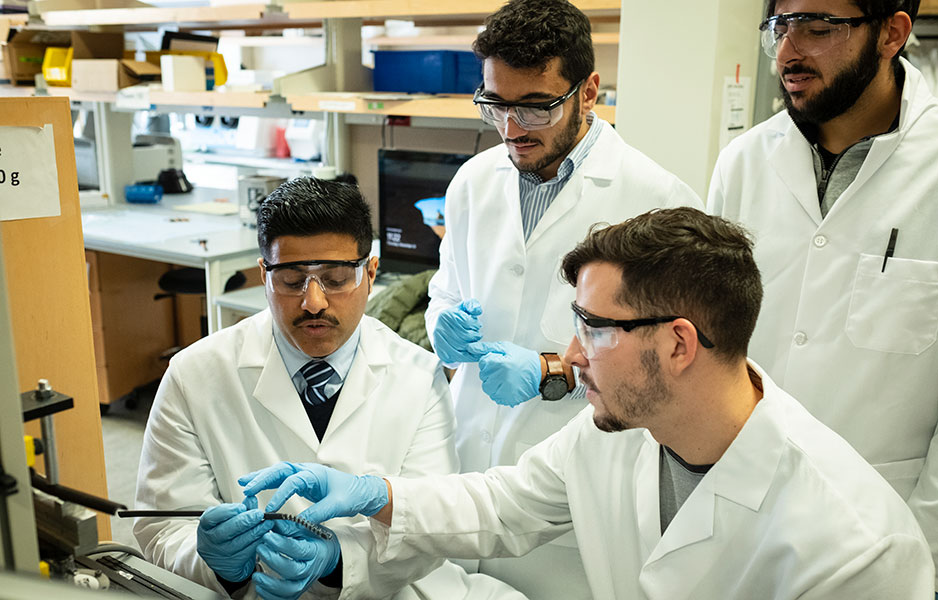

The group prepares to run a test in an engineering lab to determine how flexible and strong a 3-D printed prototype of their chest tube placement device is. (PHOTO: Joseph V. Labolito)

Creating the device has become more than just the students’ senior project.

“We’re treating it more as a long-term project,” said Tobaje, who, along with Giaddui, has been working on testing materials for the device based on the design created by Nowayti and Threeton. “We’ve already filed for an LLC.”

The group is currently testing a polymer tube guide with a flexible end that will allow doctors to control the direction of the chest tube once inserted. They’ve been using 3-D printing technology available on campus to create prototypes of the device to test.

“Next, we’ll finalize the design and then use anatomical models to test and practice with the device ourselves,” Threeton said. “Once we have the final design, we want to actually get physicians in to test it.”

Because creation and testing of the device will cost far more than the $1,000 combined budget they have for their Senior Design project, the group is currently crowdfunding the project via OwlCrowd through Dec. 15, the end of their first semester of the Senior Design capstone.

All four students said the courses they’ve taken thus far in their program have prepared them well to reach this point, teaching skills including biocompatibility testing, which they need to use for their device to ensure it’s safe to be used in humans; technical communication, so they can effectively communicate and present their research; and biomechanics, which teaches them to test the flexibility and strength of the materials they’re using.

Next semester, in the second of their two Senior Design courses, they’ll put finishing touches on their device and present it at the end of the course. Beyond their senior project, all are eager to take the device to the finish line, in hopes of potentially getting it into clinical practice someday.

“That’s the whole reason we became bioengineers,” Threeton said. “We want to provide something to be used in the hospital every day to save lives.”